Paper pulp packaging is becoming a core focus for organizations around the world as they shift away from unsustainable materials toward eco-pleasant methods. Molded pulp packaging provides a sustainable and cost-efficient way to produce high-high quality packaging which is customizable and biodegradable. 1 region driving innovation could be the introduction of high-efficiency pulp molding device, similar to the Dwellpac Semi-Hotpress Machine. These devices aid enterprises streamline manufacturing even though guaranteeing precision and dependability.This information will discover The crucial element capabilities of superior-efficiency pulp molding devices, maintenance methods for long-expression utilization, approaches to cut charges though maximizing output, And just how automation improves generation and high quality. no matter whether you're a company owner or maybe a packaging Specialist, you can expect to achieve precious insights that can help optimize your creation system.

Table of contents:

Key functions of higher-performance Pulp Molding devices

upkeep strategies for lengthy-phrase device Performance

Price-preserving Strategies in manufacturing

How Automation increases Output and excellent

critical Features of higher-performance Pulp Molding devices

significant-performance pulp molding equipment are revolutionizing how molded pulp brands work. The Dwellpac Semi-Hotpress device is a person these illustration. It stands out for its advanced Management procedure, superior clamping precision, and seamless hydraulic effectiveness. With features like precision shaping and eco-pleasant mould pressing technological know-how, it makes certain that just about every eco-welcoming box packaging products is consistent in excellent and durability. This is significant for industries needing personalized answers like food stuff packaging, electronics, and industrial custom eco friendly packaging components. this kind of devices also assistance A variety of custom molded pulp packaging requires, featuring important versatility in production.

Maintenance methods for very long-Term device functionality

keeping a pulp molding machine is critical to ensuring dependable output and maximizing its lifespan. Regular maintenance duties involve cleaning the molding surfaces, inspecting hydraulic programs for put on and tear, and guaranteeing the Command technique is up to date for peak functionality. The Dwellpac equipment is built to simplify these processes, enabling molded pulp makers to streamline maintenance. typical inspections and proactive treatment not simply minimize unanticipated breakdowns and also help manage the precision benchmarks necessary for high-excellent paper pulp packaging.

Price tag-conserving methods in Production

Price-success is a main problem for molded pulp producers. to avoid wasting charges whilst protecting quality, they can enhance material utilization by leveraging successful pulp mould pressing technology to attenuate waste, invest in Electrical power-economical equipment just like the Dwellpac Semi-Hotpress Machine to lower Vitality usage, and coach team to fully make the most of Innovative equipment to avoid glitches that lead to inconsistencies or wastage. In addition, ordering eco-helpful elements in bulk may also help make use of lower costs and minimize General creation prices. By adopting these procedures, companies can continue to be aggressive although providing substantial-good quality, tailor made eco-pleasant packaging to clients.

How Automation enhances Output and high quality

Automation has grown to be a pivotal facet of contemporary output processes. Innovative pulp molding equipment producers, for instance Dwellpac, combine automation to reinforce operational efficiency. automatic programs, by such as features like intuitive Handle panels and true-time precision monitoring, lessen the probability of human glitches. This makes certain that every mould made meets rigorous quality requirements. With automation, enterprises may also tackle significant-scale creation runs much more proficiently, Conference precise deadlines although making molded fiber packaging at competitive rates. Also, the consistent excellent reached via automation reinforces consumer have faith in in eco-welcoming packaging alternatives.

superior-performance pulp molding machines are enabling businesses to satisfy increasing demand for sustainable packaging remedies. By purchasing Sophisticated systems, businesses can create customized molded paper pulp items that not just guard the setting but will also deliver excellent performance and sturdiness. With innovative machines and considerate routine maintenance methods, companies can conquer manufacturing issues, cut down operational expenses, and offer you eco-friendly products which cater to global sustainability objectives.

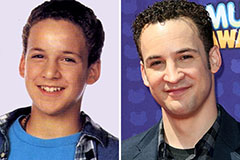

Ben Savage Then & Now!

Ben Savage Then & Now! Kelly McGillis Then & Now!

Kelly McGillis Then & Now! Kenan Thompson Then & Now!

Kenan Thompson Then & Now! Kane Then & Now!

Kane Then & Now! The Olsen Twins Then & Now!

The Olsen Twins Then & Now!